9/23/25

The Ultimate Guide to Metrology Inspection Equipment

Your customers expect more than just products that work. They expect reliability, safety, and proof that you meet the highest standards for your industry. Metrology inspection equipment helps you deliver exactly that.

In this guide to metrology inspection equipment, you’ll learn how these tools support compliance, improve efficiency, and give your business the confidence to excel in demanding industries such as medical, aerospace, and electronics. Whether you’re optimizing processes or upgrading your facilities, understanding metrology can elevate your business to the next level.

What Is Metrology Inspection Equipment, and Why Does It Matter?

Metrology inspection equipment refers to tools designed to measure dimensions, surface properties, and other physical characteristics of components with extreme precision. These tools are essential for ensuring that products meet design specifications and comply with industry regulations. They provide safety, performance, and customer trust.

Why Metrology Matters in Your Industry

- Medical devices: Implants and surgical tools must meet strict safety and compatibility standards. A microscopic defect could put patients at risk.

- Aerospace: Engine components, fasteners, and structural parts must withstand extreme conditions, where even a fraction of a millimeter matters.

- Electronics: As devices shrink, precise measurements ensure assemblies remain functional, reliable, and durable.

By embedding metrology into each stage of production, you reduce costly errors while strengthening your reputation as a manufacturer that customers can rely on.

Types of Metrology Inspection Equipment

Metrology equipment comes in many forms. A design might work better for one application over another. Below is a look at the major types you can find.

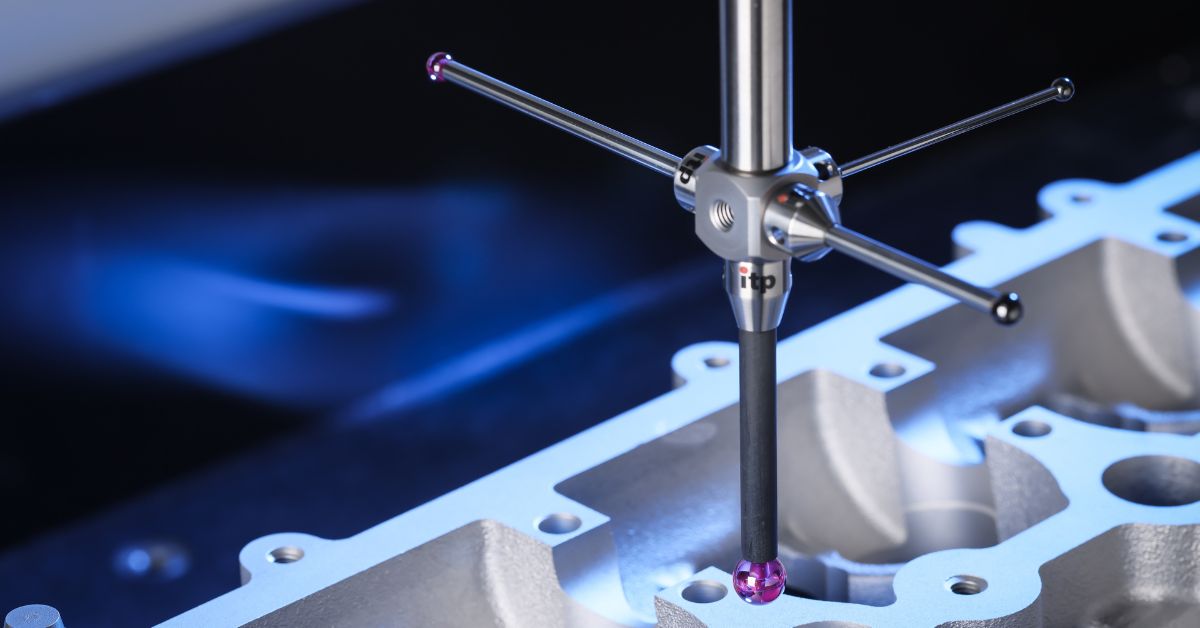

Coordinate Measuring Machines (CMMs)

CMMs use a probe to measure an object’s geometry in 3D. This metrology equipment offers exceptional accuracy for complex components. These machines are ideal for industries such as aerospace, where tight tolerances are essential for safety-critical parts.

Optical/Vision Systems

These systems utilize noncontact methods, such as cameras, lasers, or structured light, to inspect delicate or miniature components. They’re particularly useful in electronics manufacturing, where physical contact may damage intricate assemblies.

Surface Measurement Instruments

Tools, such as profilometers, evaluate surface qualities including roughness and texture. They’re essential for medical applications where smooth finishes affect functionality, for example, prosthetics or surgical tools.

Portable Inspection Tools

Wireless and handheld devices enable shop-floor measurements, offering flexibility and efficiency for off-site or large-scale applications. They’re perfect for quick inspections outside dedicated labs. Each tool has its strengths. Knowing your industry’s demands and common inspection challenges will help ensure you make the right investment.

Why Modern Metrology Tools Give You a Competitive Edge

Integrating one of the advanced metrology tools above into your operations offers far-reaching benefits. Amplify both product efficiency and product quality with these benefits:

- Improved product reliability: Precise measurements ensure components perform consistently in real-world use.

- Reduced costs and errors: Early defect detection prevents expensive rework, reduces scrap, and minimizes liability.

- Faster inspections for higher output: Automation and optimized workflows make inspection processes faster without compromising accuracy.

- Enhanced trust and compliance: Meeting international safety and quality standards secures compliance and assures customers that products are world-class.

When implemented strategically, metrology becomes a driver of growth, rather than just a cost of doing business.

Innovations Shaping the Future of Metrology

The framework of metrology is rapidly evolving in today’s modern, tech-driven world. Innovations are delivering smarter, faster, and more reliable inspections. Here are some of the most exciting developments.

Automation and Robotics

Integrating robotic systems with metrology equipment can enable direct inspection during production. This reduces downtime, streamlines workflows, and minimizes manual errors.

AI and Predictive Quality

Artificial intelligence is everywhere, including the manufacturing industry. AI is helping analyze historical data to identify patterns and predict defects before they occur.

Hybrid Systems

By combining noncontact and contact measurement methods, hybrid solutions increase versatility. They allow industries to inspect various parameters with a single device, saving time and investment.

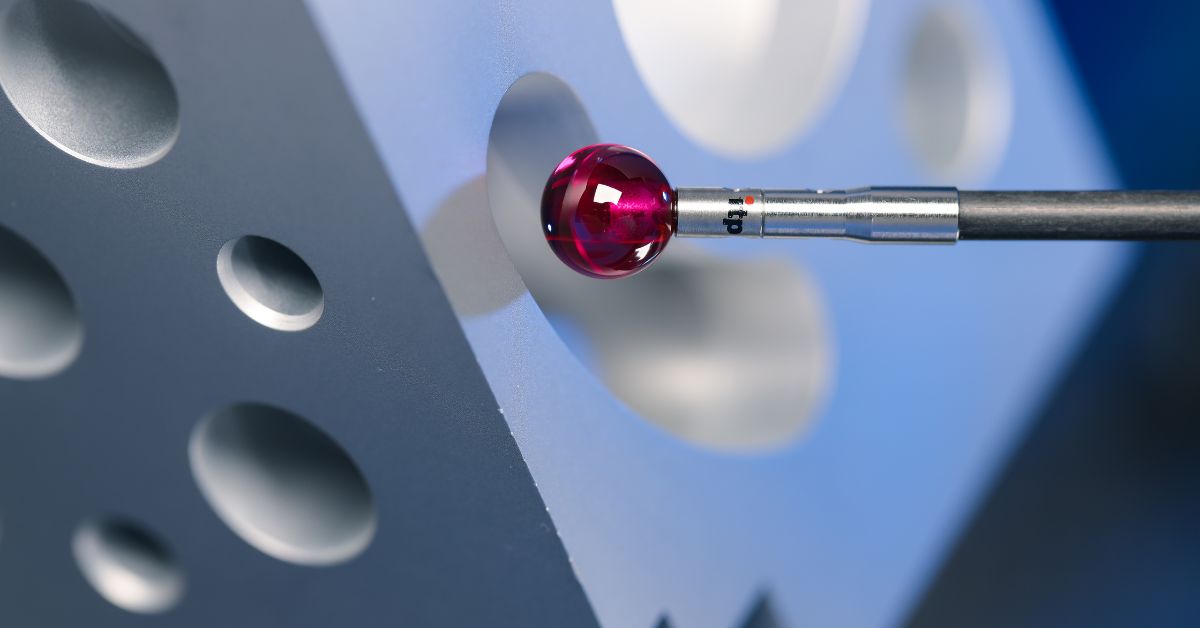

Advanced Probe Technologies

Probes with styli with diamond coating or other advanced probe materials, such as carbide, are redefining precision and durability. These specialized tools withstand abrasive surfaces and achieve high accuracy on precision-critical parts. This tech is invaluable in aerospace and electronics.

How To Choose the Right Metrology Inspection Equipment

Investing in metrology equipment is a major decision that requires careful assessment. Here’s how to make the right choice for your needs.

Match Tools to Your Industry

Consider the unique demands of your sector. Medical manufacturers may prioritize surface finish tools, while aerospace might favor CMMs for tight tolerances. Electronics often require noncontact systems to avoid damaging delicate components.

Balance Accuracy With Budget

While cutting-edge tools bring unmatched precision, you can find solutions that strike a balance between performance and cost. Match your equipment to your production volume and complexity. You won’t always need the most advanced system.

Factor in Training and Support

Even the best equipment is only as effective as the operators who are using it. Work with vendors who provide training and strong after-sales support to maximize efficiency.

Think Long-Term ROI

Although upfront costs can be high, reliable metrology equipment reduces rework, ensures compliance, and enhances quality assurance. Ultimately, this delivers significant savings over time. If you are still relying on outdated tools, investing in modern metrology solutions will equip your business for both current challenges and future growth.

Common Challenges and How To Overcome Them

Even with advanced technology, some hurdles are inevitable. Here’s how to resolve them:

- Calibration and maintenance: Regular upkeep is crucial for accurate measurements. Service agreements with vendors can keep your equipment in top shape while minimizing unexpected downtime.

- Operator skill gaps: Advanced equipment requires knowledgeable users. Offering ongoing training ensures your team operates systems confidently, maximizing their potential.

- Adapting to regulations: Standards evolve, but upgradable equipment and software make it easier to stay compliant without full replacements.

Proactively managing these issues will help you fully leverage your metrology investments while avoiding common pitfalls.

Metrology inspection equipment forms the foundation of manufacturing success to enable safe, reliable, and high-performing products across industries. Ensuring compliance, improving efficiency, and supporting innovation help businesses maintain a competitive edge.

Use this guide to metrology inspection equipment to evaluate your current processes and identify opportunities for modernization. Whether you incorporate advanced tools or invest in durable technologies, metrology ensures your operations meet both current demands and future challenges.

Ready to improve precision in your operations? Contact Itpstyli today to explore how our metrology solutions can support your industry.