12/11/25

10 Things To Know About Modular Stylus Systems

When you’re dealing with precision in manufacturing, you depend on much more than the machine. You also rely on the right stylus and setup. For manufacturers using CMMs and measurement machine tools, there are several important things to know about modular stylus systems that can improve accuracy and efficiency. From flexibility in configuration to long-term cost savings, these systems offer practical advantages that support reliable performance.

Flexibility in Configuration

One of the primary benefits of a modular stylus system is its inherent flexibility. Instead of being limited to a single, fixed-length stylus, you can assemble a configuration from various components. These systems typically consist of styli, extensions, adapters, and knuckles. This allows you to build the precise tool needed for a specific measurement task.

For example, you can create star styli to inspect features on multiple surfaces without recalibrating, or you can build long-reach probes for deep bores. This ability to break down and rebuild setups provides a dynamic solution for ever-changing inspection requirements.

Compatibility With CMMs and Machine Tools

When adopting a modular system, compatibility is a critical consideration. Styli components connect using standardized threads, with M2, M3, M4, and M5 being the most common. The thread size you need depends on the type of probe you are using: a touch-trigger or a scanning probe.

It is also important to match the shank interface with your probe module. Furthermore, the total weight and balance of the assembled stylus must be within the probe's operating specifications. An imbalanced or overly heavy configuration can lead to measurement errors or even damage the probe sensor.

Material Matters

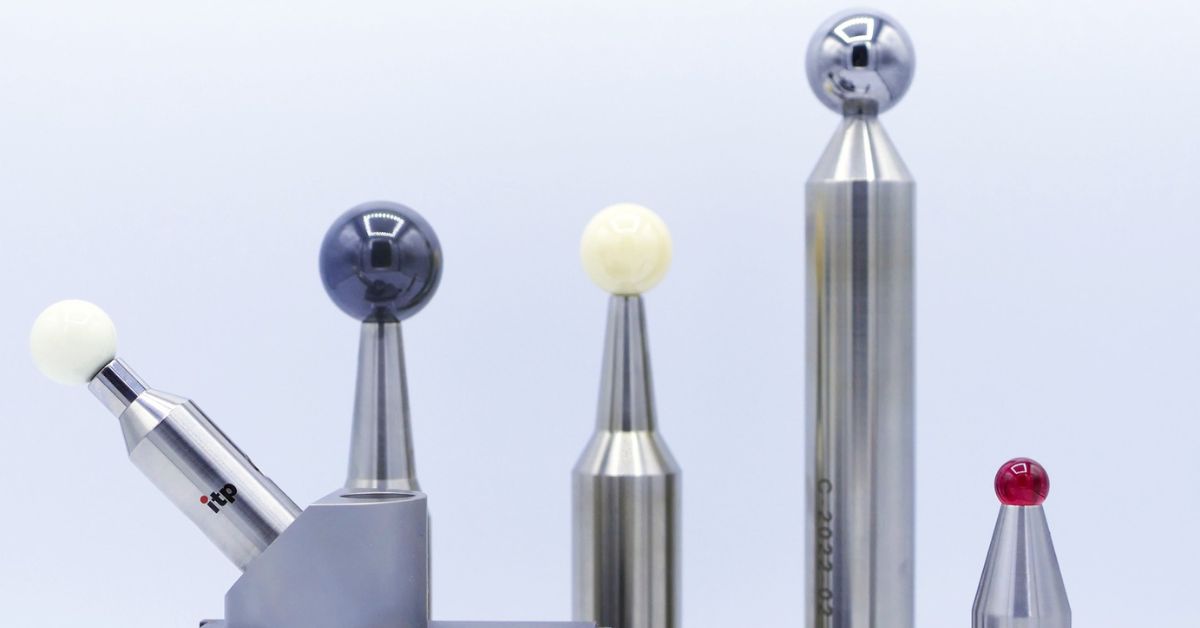

The materials used to construct styli components play a vital role in measurement accuracy and durability. Each material offers distinct properties suited for different applications.

Stem Materials

The stem directly affects your stylus's performance. Common materials include stainless steel, carbon fiber, and carbide.

Stainless steel is the most common and cost-effective choice for general applications. For longer styli where bending is a concern, carbon fiber provides excellent stiffness at a very low weight. Carbide, on the other hand, provides exceptional rigidity and stability but is heavier and best suited to shorter lengths where maximum stiffness is required. Lastly, ceramic stems are lightweight and thermally stable, protecting against changes in the inspection environment.

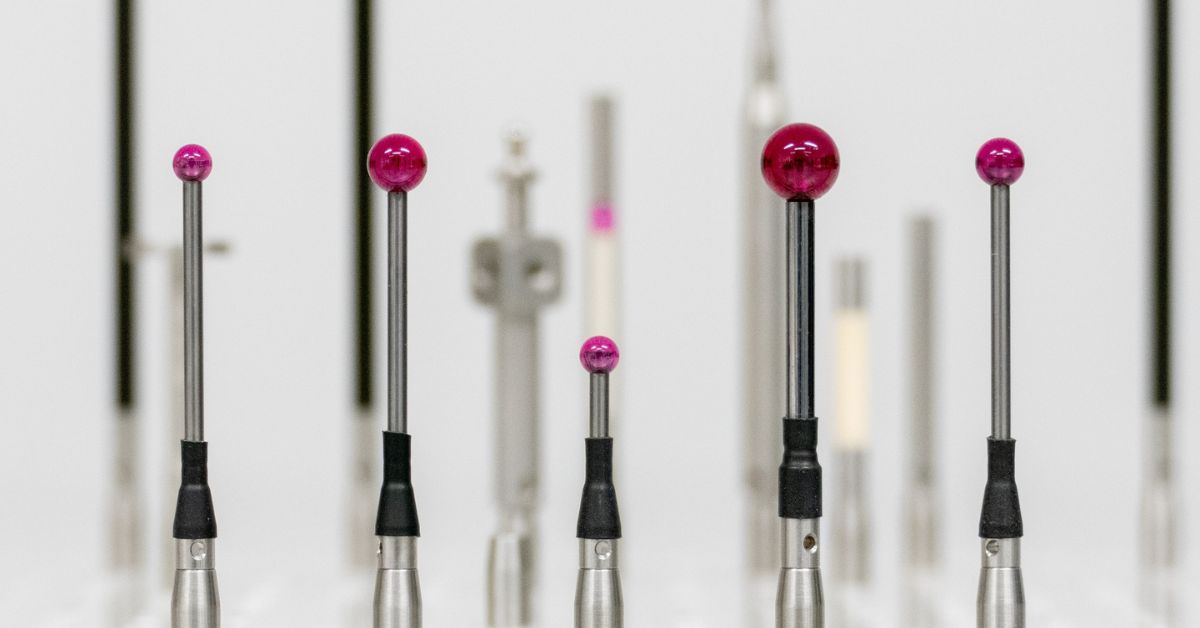

Tip Materials

The stylus tip is what makes contact with a part. Because of this, material choice is crucial. Ruby is the industry standard due to its hardness and smooth surface. For applications involving abrasive materials like cast iron, a silicon nitride or zirconia tip may be a better choice to resist wear.

When measuring soft or "sticky" materials like aluminum, a diamond-coated tip can prevent material adhesion and buildup, which would otherwise compromise accuracy.

Reduced Downtime

In a production environment that never stops, downtime is costly. Modular stylus systems help minimize interruptions to your measurement workflow. If a component becomes damaged, such as a stylus tip wearing out or an extension bending, you only need to replace that single part. You do not need to discard the entire assembly.

The ability to perform quick swaps and reduce changeover times between different inspection routines is a significant operational advantage. Standardizing on a single modular system across multiple machines can also simplify inventory management. This is because you can stock a smaller range of universal CMM styli instead of numerous application-specific components.

Reach and Accessibility

Many workpieces have features that are difficult to reach with standard styli. Deep pockets, internal bores, and undercuts present common challenges. Modular systems overcome these obstacles by allowing you to use extensions to increase the stylus's reach.

You can add knuckles and other adapters to orient the stylus tip at an angle, enabling access to features that would otherwise be impossible to measure. This enhanced accessibility allows you to gather comprehensive data across all critical areas of a part, resulting in a more complete and reliable quality assessment.

Improved Accuracy Through Rigidity

A key factor in measurement accuracy is the rigidity of the stylus stack. Any bending or deflection in the stylus during measurement will introduce errors. The design of modular systems is to maximize rigidity, even in long configurations.

The quality of the joints between components is essential; they must connect securely to prevent any movement. While adding more joints can potentially decrease rigidity, using high-quality components and stem materials helps maintain stiffness. It is also important to manage overhang and total mass, as these factors contribute to deflection and dynamic errors during high-speed scanning.

Custom Component Solutions Are Possible

While standard modular components cover a wide range of applications, sometimes a unique challenge requires a specialized solution. This is another area where modularity shines. It is possible to work with a supplier to develop custom components tailored to your exact needs.

Experts, like istpystyli, can provide advice on optimal geometry, material selection, and joint design for a specific application. Whether you need an unusually shaped stylus tip, a specific-length extension, or a complex multi-tip cluster, a custom-designed component can be integrated into your existing modular system to solve even the most demanding measurement problems.

Accessories Enhance Performance

Beyond the basic building blocks of styli and extensions, a variety of accessories can enhance the performance and usability of a modular system. For instance, you could use color-coded rings or labels to identify different stylus assemblies, making it easy for operators to quickly select the correct tool for a job.

Workers can incorporate break-stems or crash protection to safeguard the probe from damage in the event of an accidental collision. Specialized toolkits and racks help keep all your modular components organized and readily accessible, further streamlining your process.

Cost Efficiency Over Time

The initial investment in a modular stylus system might be higher than purchasing a few simple, one-piece styli. However, the long-term cost efficiency is substantial.

As mentioned, the ability to replace individual components rather than entire assemblies significantly reduces replacement costs. The system's flexibility lets you adapt to new measurement tasks without purchasing an entirely new set of styli. By standardizing on a modular platform, you can create a versatile toolkit that grows with your needs and provides a better return on investment over the life of your CMM.

Future-Proofing Your Measurement Setup

Investing in a modular stylus system is a way to future-proof your quality control processes. As manufacturing grows more complex and part tolerances become tighter, your measurement needs will evolve.

A modular system provides the adaptable foundation needed to meet future challenges. You can easily integrate new materials, new tip geometries, and new configurations as they become available or as your product designs change. This forward-thinking approach ensures that your measurement capabilities can keep pace with innovation.

As you can see, there are many things to know about modular stylus systems that can benefit your operations. At itpstyli, we are committed to providing the highest quality modular components to ensure your measurement systems are both precise and adaptable. Our extensive inventory includes a diverse range of styli, accessories, and custom solutions designed for any precision industry.