Diamond Coated UltraScanning Styli

Measurement challenges demand more than standard solutions—that’s where diamond styli excel. Engineered to tackle the toughest tasks, these diamond styli for metrology applications excel in long-cycle scanning of abrasive materials or soft metals, ensuring accurate results without compromise. itpstyli offers a wide selection of diamond-coated styli to address the problems associated with using ruby and silicon nitride spheres in extreme measurement applications like long-cycle scanning of abrasive or very soft materials. Avoid premature wear and material “pick-up” with UltraScanning diamond styli from itpstyli.

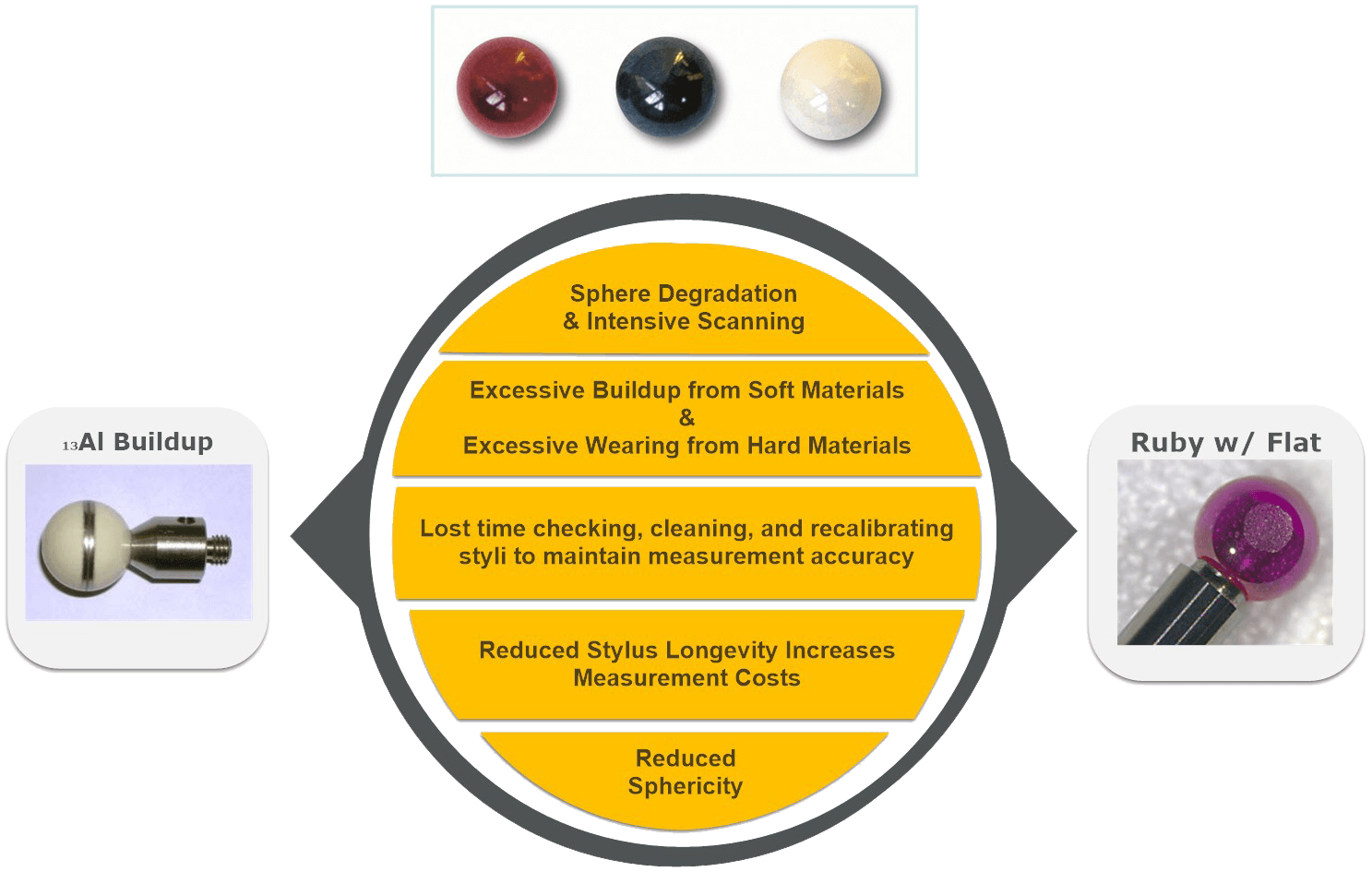

The Problem with Intensive Scanning using Ruby, Silicon Nitride or Zirconium

During intensive scanning of abrasive and very hard materials like silicon carbide, conventional sphere materials are likely to develop “flats” from excessive wear. On the other extreme, softer materials like aluminum can transfer to the sphere, causing “build-up.” In either extreme, sphericity and roundness are compromised, and measurement accuracy suffers. The innovative solution of a metrology-grade ceramic sphere with an ultra-thin styli with diamond coating resists wear and eliminates material buildup. Streamline your operations and increase efficiency for applications that demand reliability and superior results.

The Solution: UltraScanning Diamond-coated Styli

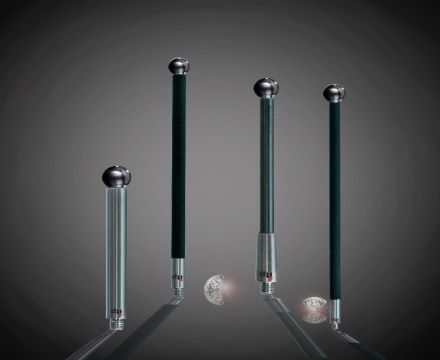

itpstyli’s UltraScanning line of styli start with a metrology grade ceramic sphere, the surface of which is diamond-coated to a thickness of approximately 0.03 mm. The balls are polished in a highly complex process to ensure Grade Five form and are mounted to the stem using a proprietary in-house active-brazing procedure to maximize durability while maintaining precision.

Whether measuring silicon carbide or aluminum, itpstyli’s diamond styli maintain their integrity over extended use, providing prolonged reliability for critical tasks. Precision-engineered for professionals, these styli offer consistent measurement accuracy to help you tackle your most challenging applications with confidence.

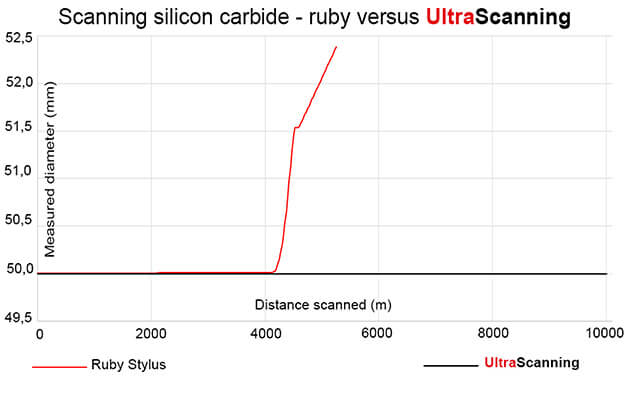

Wear Resistance Test Data - UltraScanning vs. Ruby Styli

itp conducted a test to prove and measure wear resistance. The UltraScanning diamond-coated sphere was compared to the industry standard ruby sphere (which is harder than silicone nitride). The work-piece material was silicon carbide, one of the hardest ceramic materials available. In addition, the test piece had an extremely rough surface finish of 16 Ra (comparable to a grade 80 sandpaper). The test was executed using a highly recognized metrology scanning system.

- Each stylus was calibrated, and

- then put through a series of scanning cycles, each with a scanning speed of 25mm/sec, followed by

- 2 calibration checks to measure for potential wear.

The standard ruby material sphere (which is harder and more wear resistant than Silicon Nitride) first started to exhibit wear at approximately 11,500 feet of scanning. The UltraScanning stylus was tested through approximately 33,000 feet of scanned distance with no deterioration in calibration performance and no visible marking or wear. The following graph illustrates this data.

The UltraScanning Diamond-coated stylus test was concluded at 33,000 feet of scanned material when no measurable or visible wear could be identified. It was equally clear that the ruby sphere began to diverge and lose its roundness in 1/3 the distance, as seen on the right in this optical comparison. If extreme scanning of very hard and abrasive (or very soft and transferrable) materials is part of the measurement requirements, using itpstyli’s UltraScanning styli will be justified by longer life and reduced maintenance.

M5 UltraScanning Styli

Full Range of M5 Diamond Coated Styli

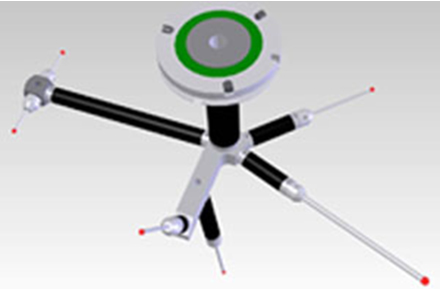

UltraScanning for VAST XXT

Full Range of Scanning Styli for M3 XXT Systems

Customized UltraScanning Configurator

Design your Own Diamond-coated Styli

M5 UltraScanning Styli

Full Range of M5 Diamond Coated Styli

UltraScanning for VAST XXT

Full Range of Scanning Styli for M3 XXT Systems

Customized UltraScanning Configurator

Design your Own Diamond-coated Styli