9/12/25

The Advantages of Using a Ruby Ball Stylus

When precision matters, a fraction of a millimeter can determine success or failure. Regardless of the type of product you’re manufacturing, the stakes are high, and reliable measuring tools are crucial for achieving accurate and repeatable results.

For manufacturers seeking an edge, ruby ball styli are the gold standard. Built to deliver superior accuracy, unmatched durability, and consistent reliability, these are the tools of choice for industries driven by precision. Whether you’re optimizing production or complying with regulations, understanding the advantages of using a ruby ball stylus makes it an important asset for quality control teams.

Why Stylus Selection Matters in Manufacturing

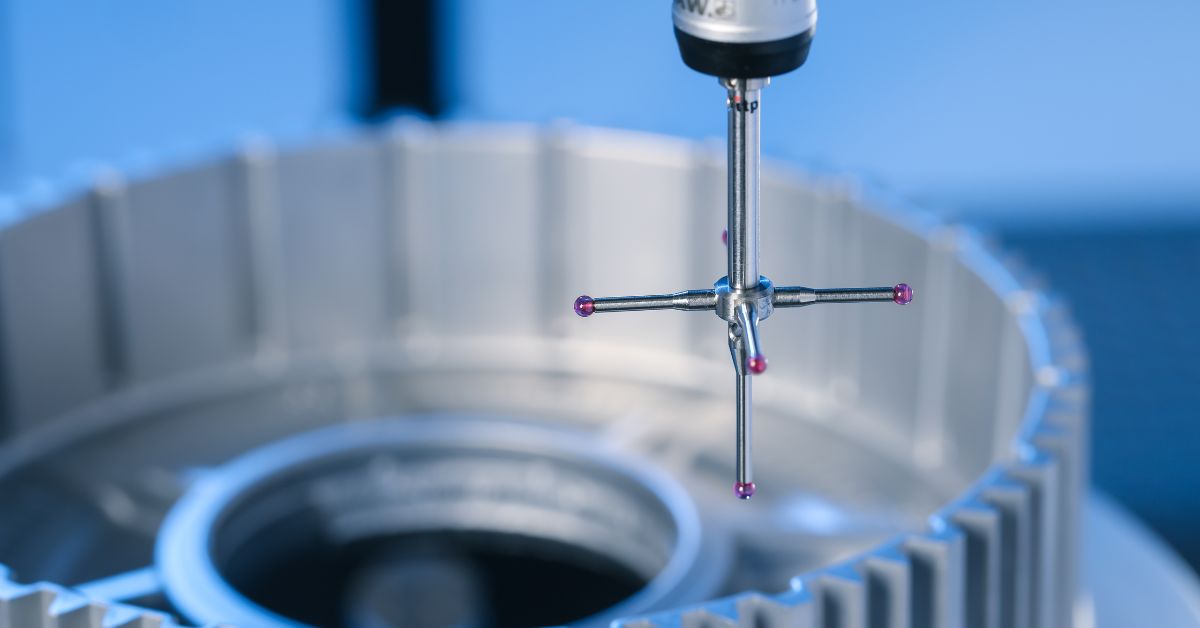

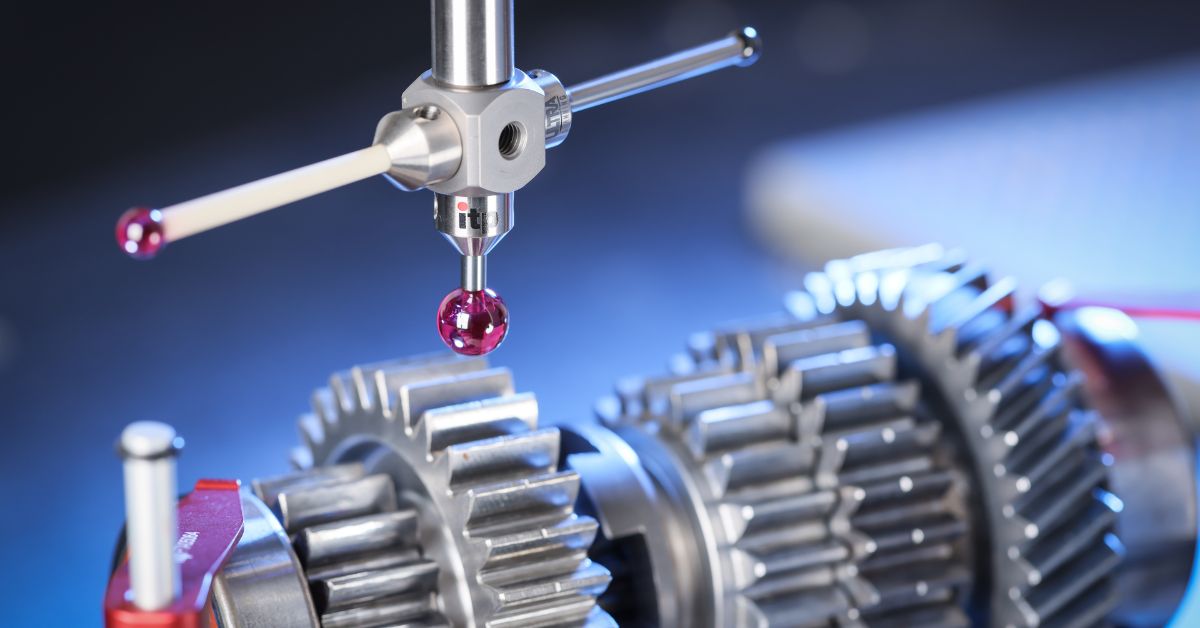

Styli may be small, but they play an outsized role in measurement accuracy. As the only direct point of contact between a coordinate measuring machine (CMM) and a part, your choice of stylus determines the reliability of every reading. Therefore, this accessory is a key factor in achieving accurate results.

Choosing the wrong stylus sets off a chain reaction of issues. Measurement discrepancies can lead to rework, missed tolerances, compliance failures, and inflated production costs. These risks are especially pronounced in high-stakes sectors like aerospace, where safety-critical components leave no room for error. A ruby stylus is an investment in reliable operations, safeguarding quality, compliance, and efficiency from the very first measurement.

Key Advantages of Ruby Ball Styli

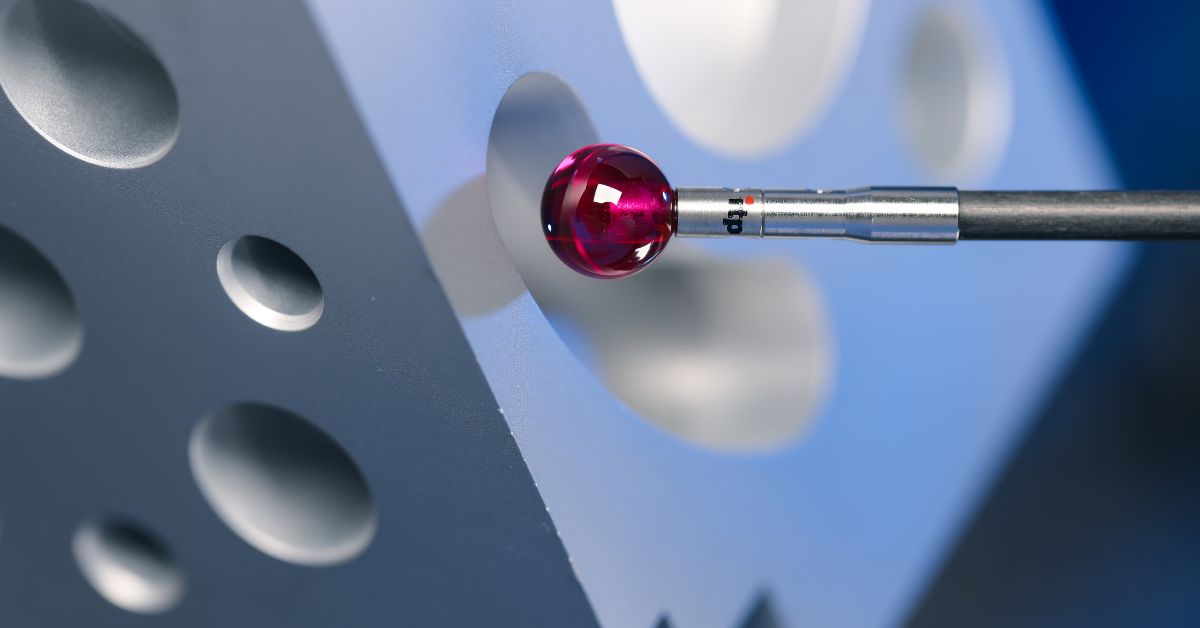

Ruby has long been the benchmark for stylus performance. Its strengths are especially valuable for industries where precision is nonnegotiable.

Superior Accuracy

Ruby’s natural sphericity makes consistent and exact contact with the surface you’re measuring. This precision minimizes uncertainty and provides repeatable results, even with complex geometries. For applications where micrometer-level tolerances matter, ruby delivers accuracy without compromise.

Exceptional Durability

Manufacturing environments demand tools that can withstand heavy use. Ruby’s hardness and resistance to wear means it retains its shape and smooth surface, even after thousands of measurement cycles. The result is fewer replacements, less downtime, and measurements that remain dependable in high-volume settings.

Reliability in Challenging Conditions

Production floors aren’t controlled environments. Temperature shifts, humidity, and varying materials can influence results. However, ruby styli remain stable. Whether verifying the dimensions of aerospace alloys or handling the delicate surfaces of microelectronics, ruby instills confidence that measurements will hold steady, regardless of external conditions.

Minimal Maintenance and Low Calibration Drift

Since ruby is so durable, you won’t need frequent recalibration due to frequent use. Its stability leads to consistent results and keeps production running smoothly with less downtime. Ruby also gives quality control teams confidence that measurements remain reliable, shift after shift.

Cost Efficiency

Exceptional long-term value is a major advantage of ruby styli. Their durability results in fewer replacements and less frequent recalibrations, which leads to lower operational costs. Additionally, the consistent performance of ruby styli eliminates excess material waste and rework, streamlining production and optimizing resources.

Industry Applications: Where Ruby Makes the Difference

The value of ruby becomes most evident in the industries that rely on it daily.

Medical Manufacturing

Precision is a critical requirement in medical device production. Surgical tools, implants, and diagnostic devices all require exact measurements to remain effective and safe for use. Ruby ball styli help meet these stringent demands for dimensional accuracy and compliance with international standards.

By consistently delivering reliable measurements, ruby styli play an essential part in manufacturing products that can improve and save lives. Whether it’s a stent or a prosthetic joint, manufacturers gain confidence knowing their tools aid in the production of components with zero compromises.

Aerospace

Few industries demand the level of exactness that aerospace does. From turbine components to structural materials, every piece is mission-critical. CMM probe tips made with ruby are capable of handling these high-stakes tasks. This advantage offers measurement reliability that aligns perfectly with the exact tolerances defined by regulators.

Material compatibility is another advantage. Ruby works efficiently with high-performance alloys commonly used in aerospace, delivering exceptional accuracy and durability over extended periods of use.

Electronics

The miniaturization of components in the electronics sector means manufacturers often work at microscopic scales. Ruby styli handle these demands with finesse for smooth contact and precise results. By preventing damage to delicate parts like microchips and printed circuit boards, ruby enhances accuracy and efficiency. No matter how small the component or how complex the design, ruby continues to perform without compromise.

A Quick Comparison: Ruby vs. Alternatives

Ruby ball styli are widely recognized as the benchmark for accuracy and durability, but other materials can be valuable in specific situations. For example, silicon nitride is often chosen to reduce aluminum buildup, diamond-coated styli excel when used on abrasive surfaces, and zirconium oxide offers toughness for certain applications.

These alternatives have their place, but for most medical, aerospace, and electronics environments, ruby provides the best balance of precision, wear resistance, and stability. Its versatility makes it the preferred choice for quality managers who need reliable results across a wide range of measurements.

Maximizing Stylus Performance

To get the most from your ruby ball stylus, implementing certain best practices can improve accuracy and prolong its service life. They include:

- Always store styli securely, and avoid impacts that might compromise precision. Damage can undermine their accuracy, so preventative care is invaluable.

- Regularly inspect the stylus for signs of wear or damage. Identifying issues early can prevent unexpected disruptions in workflows and safeguard measurement reliability.

- Dust, oils, or residue can interfere with performance. Keeping the working area clean and the stylus free from contaminants contributes to consistent accuracy across applications.

- Selecting the appropriate stylus size, shape, and material for specific measurement tasks leads to optimal performance and accuracy.

For industries where every measurement defines success, the advantages of using a ruby ball stylus are undeniable. Its unmatched precision, durability, and dependability make it the ideal tool for manufacturing sectors that demand nothing but perfection.

At Itpstyli, we are committed to delivering precision tools that elevate quality control in manufacturing. From enhancing accuracy to promoting long-term reliability, our products are invaluable assets. With our help, you’ll unlock consistent performance that protects your production and reputation. Contact Itpstyli to explore how our ruby ball styli can bring unparalleled precision to your operations.